PA Car Part, Auto Chassis Parts Car Accessories Plastic Injection Molds

Package Size 21.00cm * 22.00cm * 32.00cm Package Gross Weight 30.000kg #1 Very high production rates One of the most app

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | WD-036 |

| Plasticizing Way | Plunger Type |

| Clamping Way | Mechanical |

| Automation | Automatic |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008, QS |

| Transport Package | Packing by Sea |

| Trademark | OMMO |

| Origin | China |

| Production Capacity | Amount |

Packaging & Delivery

Package Size 21.00cm * 22.00cm * 32.00cm Package Gross Weight 30.000kgProduct Description

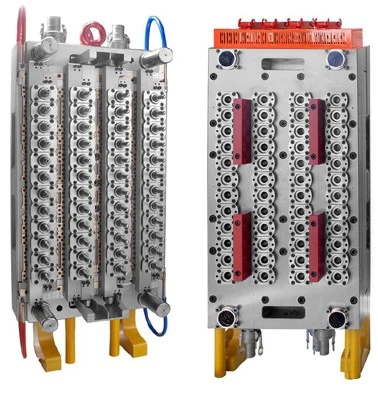

One of the most appealing characteristics of plastic injection molding as opposed to other processes is its very high production rates. Depending on the complexity of the design, the size of the part being molded, and other factors, individual molds can produce hundreds or even thousands of finished parts per hour. This allows manufacturers to keep costs low, while still benefiting from a fast turnaround time for their products.

#2 High tolerance precision

With the use of this process, you can produce high tolerance precision parts. A mold is used to create the shape of your part. The molds are held to very close tolerances by design. For example, if you need to make a thousand identical parts, you can use the same mold and they will all be exactly the same size and shape.

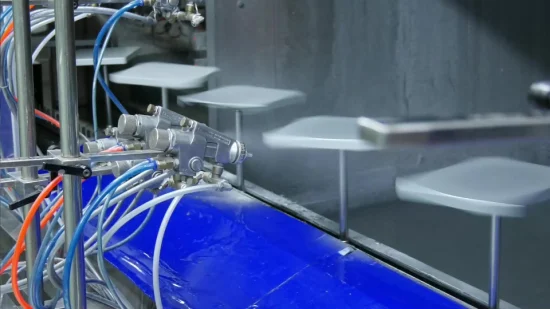

#3 Low labor costs

Compared to other manufacturing processes, plastic injection molding is relatively labor-free once a mold has been manufactured. Many companies that offer injection molding services are able to produce large quantities at a very low price point because they do not need to hire much labor for this type of work. This allows them to remain competitive in today's market and keep prices low for consumers.

#4 Environmentally friendly

When compared to other manufacturing processes like CNC machining, which creates a lot of waste by cutting away at raw material, plastic injection molding is a much more eco-friendly solution.

#5 Very durable

Another great benefit of plastic injection molding is the ability to create very durable products that do not scratch or break easily. You can also choose from different types of plastics based on your product's needs, like an impact-resistant or heat-resistant plastic.

#6 Variety of plastics available for choices

There are a variety of plastic resin material options to choose from for use in the plastic injection molding process. Each material has its own unique properties; therefore, understanding the differences between them is crucial to ensure selecting the most suitable material for your intended application.